|

BERKELEY, CA — A new generation of solar cells

that combines nanotechnology with plastic electronics has been launched

with the development of a semiconductor-polymer photovoltaic device by

researchers with the U.S. Department of Energy's Lawrence Berkeley National

Laboratory (Berkeley Lab) and the University of California at Berkeley

(UCB). Such hybrid solar cells will be cheaper and easier to make than

their semiconductor counterparts, and could be made in the same nearly

infinite variety of shapes as pure polymers.

|

|

|

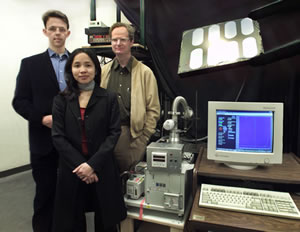

| Janke Dittmer, Wendy Huynh, and team

leader Paul

Alivisatos created tiny solar cell assemblies (shown held by

a tweezer, upper right) using nanoscale semiconducting rods

of polymer and cadmium selenide |

|

Paul Alivisatos, a chemist who holds a joint appointment with Berkeley

Lab's Materials Science Division (MSD) and UCB's Chemistry Department,

led the research team, who reported their hybrid solar cell development

in the March 29, 2002 issue of the journal Science. Other members

of the team were Wendy Huynh, a graduate student with UCB's Chemistry

Department, and Janke Dittmer, an MSD staff scientist.

"We have demonstrated that semiconductor nanorods can be used to

fabricate readily processed and energy-efficient hybrid solar cells together

with polymers," says Alivisatos, a leading authority on the production

of nanosized semiconductor crystals and director of the Molecular Foundry,

a center for nanoscience now being established at Berkeley Lab.

The use of solar, or photovoltaic, cells — devices that can absorb and

convert light into electrical power — has been limited to date because

production costs are so high. Even the fabrication of the simplest semiconductor

cell is a complex process that has to take place under exactly controlled

conditions, such as high vacuum and temperatures between 400 and 1,400

degrees Celsius.

Ever since the discovery in 1977 of conducting plastics (polymers which

feature conjugated double chemical bonds, that enable electrons to move

through them), there has been interest in using these materials in the

fabrication of solar cells. Plastic solar cells can be made in bulk quantities

for a few cents each; however, the efficiency with which they convert

light into electricity has been quite poor compared to the power-conversion

efficiencies of semiconductor cells.

"The advantage of hybrid materials consisting of inorganic semiconductors

and organic polymers is that potentially you get the best of both worlds,"

says Dittmer. "Inorganic semiconductors offer excellent, well established

electronic properties, and they are very well suited as solar cell materials.

Polymers offer the advantage of solution processing at room temperature,

which is cheaper and allows for using fully flexible substrates, such

as plastics."

At the heart of all photovoltaic devices are two separate layers of materials,

one with an abundance of electrons that functions as a "negative

pole," and one with an abundance of electron holes (vacant, positively-charged

energy spaces) that functions as a "positive pole." When photons

from the sun or some other light source are absorbed, their energy is

transferred to the extra electrons in the negative pole, causing them

to flow to the positive pole and creating new holes that start flowing

to the negative pole. This electrical current can then be used to power

other devices such as a pocket calculator.

In a typical semiconductor solar cell, the two poles are made from n-type

and p-type semiconductors. In a plastic solar cell, they're made from

hole-acceptor and electron-acceptor polymers. In their new hybrid solar

cell, Alivisatos, Huynh, and Dittmer used the semicrystalline polymer

known as poly(3-hexylthiophene), or P3HT, for the hole acceptor or negative

pole, and nanometer-sized cadmium selenide (CdSe) rods as the positive

pole.

"We chose P3HT because it can be processed in solution and has been

used by many research groups around the world who are working on plastic

transistors," says Huynh. "Also, it is the conjugated polymer

with the highest hole mobility found so far. Higher hole (and electron)

mobility means that charges are transported more quickly, which reduces

current losses."

The cadmium selenide rods measured 7 nanometers in diameter and 60 nanometers

in length (a nanometer is one billionth of a meter, less than one-hundred

millionth of an inch). Alivisatos led an earlier study in which the technique

for growing semiconductor nanocrystals into two-dimensional rods was first

developed. Prior to that work, nanocrystals had always been grown as one-dimensional

spheres. Using rod-shaped nanocrystals rather than spheres provided a

directed path for electron transport to help improve solar cell performance.

"With CdSe rods measuring 7 nanometers by 60 nanometers, our hybrid

solar cells achieved a monochromatic power conversion efficiency of 6.9

percent, one of the highest ever reported for a plastic photovoltaic device,"

says Alivisatos. Monochromatic power efficiency measures the ability to

convert room light (which is mostly visible light) into electricity.

The Berkeley researchers prepared their solar cells by codissolving the

nanorods with the P3HT and spin-casting the hybrid solution onto a glass

substrate. They found that by keeping the length of the rods constant

while modifying the diameter enabled them to tune the absorption spectrum

of the cells so that it overlapped with the solar emission spectrum. This

not only enables their hybrid cells to collect more light than typical

plastic solar cells, but it also opens the door for high-efficiency devices

in the future, such as tandem solar cells.

Although the efficiency of the Berkeley hybrid cells for converting sunlight

into electricity was only 1.7 percent at A.M. 1.5 (when the sun is at

a 41.8-degree angle to the horizon), which is far off the mark of the

best semiconductor solar cells, Dittmer says there is ample opportunity

for improvement.

"The most important step is to increase the amount of sunlight absorbed

in the red part of the spectrum, which we can do by going to other semiconductor

materials such as cadmium telluride. Also, our published hybrid solar

cells have a very simple structure, in order to investigate the science

behind them. In the future, many engineering tricks can be applied to

make the cells more efficient." The Berkeley researchers have already

been approached by companies that are interested in commercializing this

technology.

Berkeley Lab is a U.S. Department of Energy national laboratory located

in Berkeley, California. It conducts unclassified scientific research

and is managed by the University of California.

|